COFF CONCEPTION:

Anyone who aims to run a successful beer brewing business has to face up to a huge array of challenges. How can I place a brewhouse into a very limited space while all functions enabled? How can I satisfy my guests’ increasing demands without excessive energy consumption? Who can free me from the heavy lifting of controlling every factor of brewing? Who can support me with the best, most reliable technology and after-sales service?

Our dedicated team of innovative professionals will work with you to create a perfect solution from design, engineering, crafting, and installation for your individual project needs, no matter start-ups or experienced brewers. Our production team is highly skilled and always focusing on ways to make our systems work more efficiently, they will provide you with production status updates every step of the way.

DESIGN FEATURES:

1.All tanks are insulated, which is a real boost to energy efficiency, and the brewer’s workspace is cooler and safer!

2.Double hot water tank capacity, CIP operation at the same time as brewing, which is really helpful You can do this when you are cleaning or brewing, or if you want a second batch, it can give you a good start for your second batch!

3.There’s a countdown timer so you can have hot water ready to brew when you set it up ahead of time, ready to brew up when you walk in the door

4.When coming out of the mash tun and going to the boil, it heats up quickly at the end of the stirring

5.Very adjustable evaporation rate by use 1 or 2 or 3 heating elements according to your requirement

6.The brewing process is a very logical hard hose connection that saves labor by not having to lug hoses around

7.All tanks contain cip cleaning balls

8.Self-contained heat exchanger

9.The footprint is very small, all the features are on one base which is absolutely amazing, you just pull it out of the container, it has some casters and you can roll it into place, take the casters off, put it down and connect it to power and water and you’re ready to brew, it’s very easy to clean and you have CIP anywhere you need it.

Our Services:

Tailor-made: 6-year experience

Production facility: 3,000m2

Local support: 18 countries

Annual turnover: 30 million Yuan

After sale: technical support on installation

Warranty: a three-year quality warranty, provide remedy free of charge.

Packaging & Shipping:

LCL: plastic film and bubble film, fumigation free wooden case.

FCL: plastic film and bubble film, especially designed iron frame with fixtures for sea shipment.

Company Information:

Established

in Ningbo, China, Coff is a leading manufacturer specializing in

beverage equipment. Our collections include but not limited to beer

brewhouse, fermentation vessel, bright beer tank, HLT&CLT, CIP cart,

grist hopper, hop back, mill, etc.

Quality, productivity, and

flexibility are the key focus for Coff. Thanks to its vertically

integrated manufacturing processes from raw materials purchase, welding,

polishing, assembly to packaging, we provide a customization and OEM

service from design concept through to cost-effective fabrication.

Application:

Being

one of the most important manufacturers for premium brewing equipment

in China, we’ve been working with a number of leading brands over the

years, and our products have been well accepted and recognized by the

equipment industries/breweries, for their excellent quality, design,

function and service.

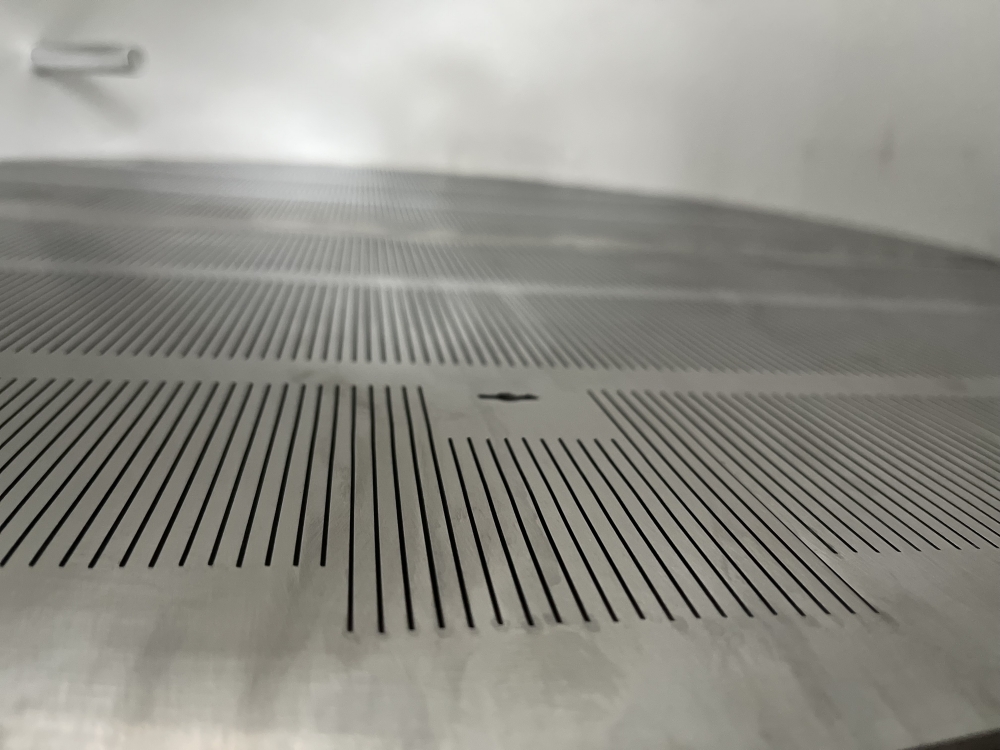

MANUFACTURING PROCESS:

●A vertically integrated manufacturing processes from raw materials purchase, welding, polishing to packing

●100% Stainless Steel 304, only quality materials are used

●Modern technology: TIG welding, spot welding, laser welded on dimple jacket and tank bottom, trace welded pipes

●Strictly controlled under ISO9001 quality management system

Top Quality:

● Extensive quality control system (following ASMI standard)

● In-process inspectors

● At least 2 times operation test before delivery

● Fully functional FAT capabilities

● Dedicated in-house FAT technicians

● Non-destructive Examination

● Material traceability reports

● Certification documents

● Integrated manufacturing processes

● 100% quality SS304 with 2B finish

Dear customers,

Thanks for your attention and interest in Coff products.

Should you have any questions or request further information on brewing

equipment, please feel free to liaise with us. We shall be more than

happy to assist your business.

Best regards.

Coff (Ningbo) Machinery Co., Ltd.

[ad_2]